This past year has taken me on both an educational and spiritual journey. Through this I gained the ability to grasp a greater understanding of who I am as a designer. I feel at this final stage it is extremely valuable to reflect on the experiences gained.

I knew from the offset that I wanted to create something that allowed the user to be completely immersed into a meditative experience. I have always loved products and art pieces that create a synesthetic state in the user and wanted to create a product that had this underlying theme. I found myself one day early in the year making tea, the same way as always, with my self-constructed tea set. While I was drinking I was struck with a sudden realisation, why do I make tea this way? Why do I drink tea every evening after my meal? It was because of the state of relaxation it evoked. From this point on I knew I wanted to work with tea.

I began by studying tea as an art form and spiritual way of life (Taoism) alongside field research into the current tea perception in our western world. These were both extremely valuable approaches and from them I was able to strike an effective balance in a design sense. From researching into the art form of tea in ancient China and Japan I continually gained a deeper respect for the project and what I was trying to create with it. The research also allowed me to understand what form of design I would like to do in my future career. The Zen state of mind that is present in parallel to Taoism speaks of glory in the moment and about enjoying the simple experiences of life. From this I now know that I would like to design thought provoking products that allow for the amplification of an experience.

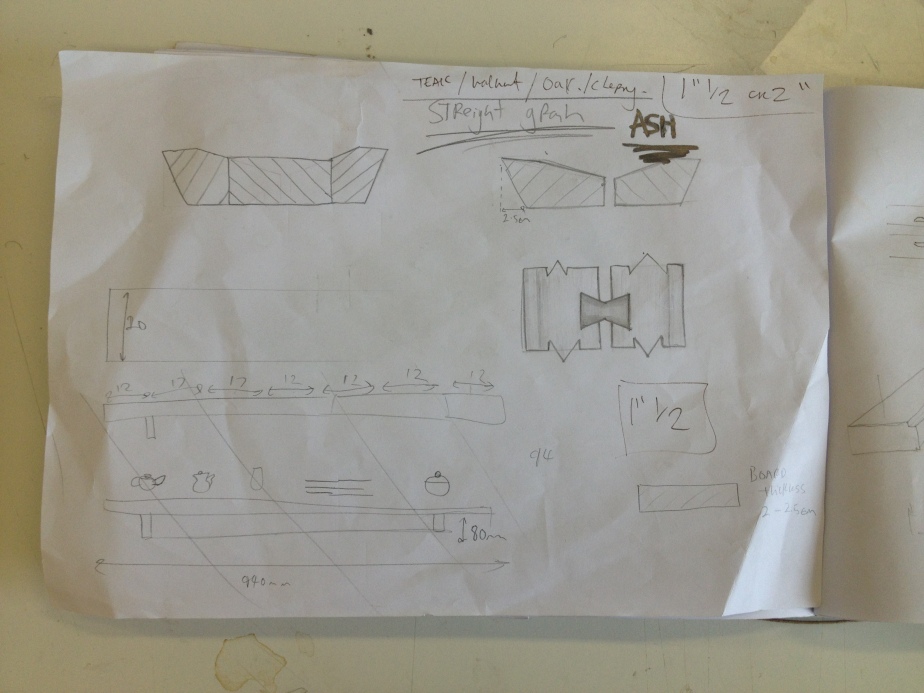

One of the most significant design changes that I made through the year came from, what I believe, to be the result of getting to close to your design, (an inevitable reaction when working on something this long). In the early stages of my design I was trying to implement almost all aspects of the Chinese Gongfu Ceremony (a traditional tea ceremony). This appealed directly to me because I personally would love to learn how to correctly complete the detailed process. However I understand now, by conducting field research, that most people will purely perceive my design as over complicated and unnecessary. I have since created a simplified version of the process and it can be found as the core of my final design.

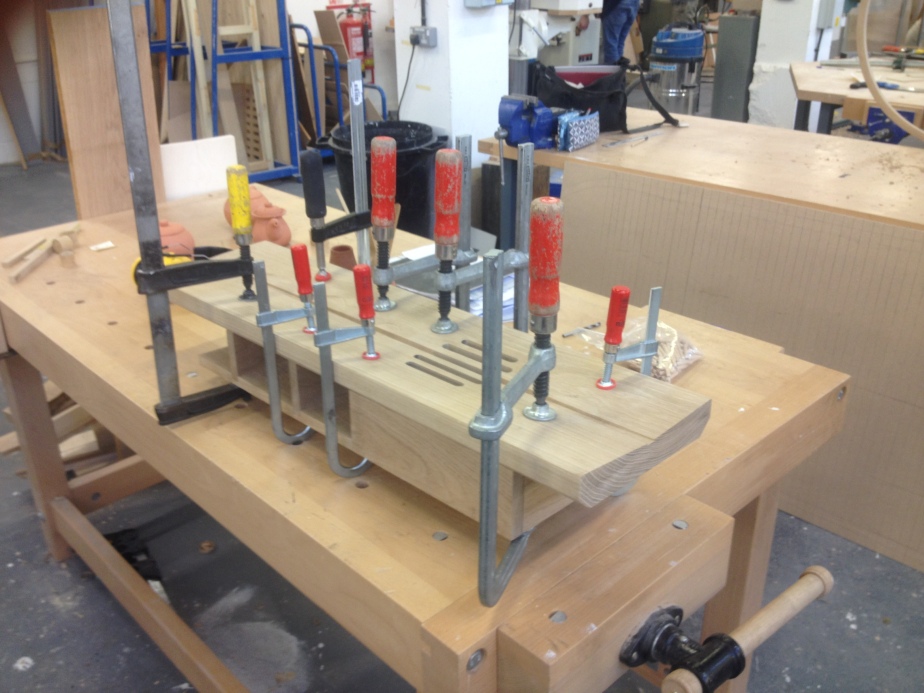

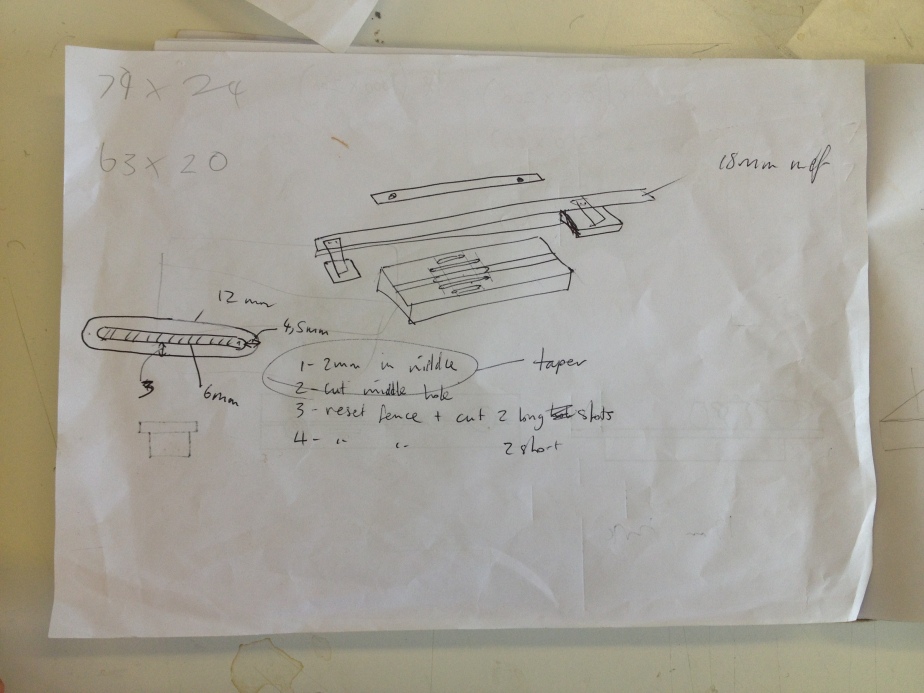

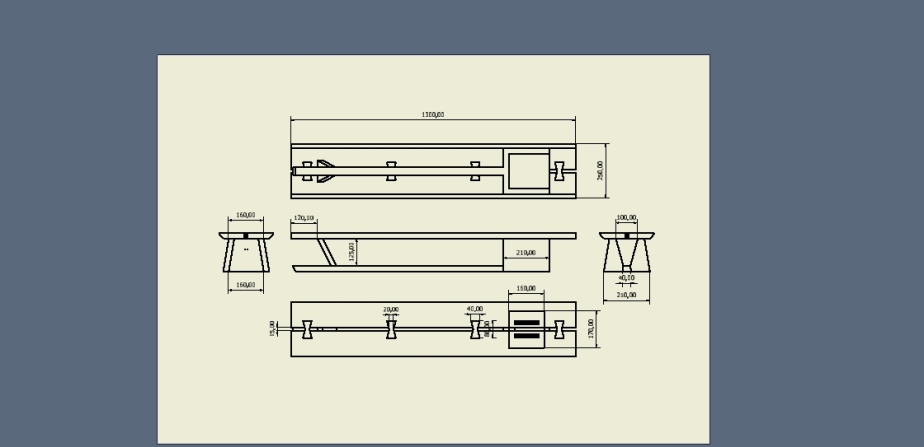

I also had the opportunity to learn and apply new crafting techniques. I would call myself a design craftsman due to my hands on approach to my design process. Before this project I had never worked in any form of casting or ceramic, a vital part of any craftsman’s arsenal. Through the “Essence of Tea” I was able to develop both of their skills and apply them to my final design. I am extremely pleased that I was able to obtain these skill sets before leaving university. I also had the chance to deepen my understanding of fine wood craft, through the construction of the “Essence of Tea” oak table. Many of the final design decisions I made this year came from gaining a deeper understanding of how materials react to particular subjected environments and working techniques.

It was very important to me that all the design decisions that I made through the design process accurately represented the core values of the product. This can be seen very clearly in the material choices. The product is constructed from 100% natural materials and all natural product finishes are used. The products visual language promotes the users experience by being mainly constructed from red earthenware clay and American white oak. Both of these key materials are even finished to appear as natural as possible by leaving the exterior of the clay unglazed and finishing the oak with Chinese tung nut oil. The hand crafted approach to the build of the “Essence of Tea” has given it a valued personal character and will develop its own personality as it is used more and more.

The project has opened my eyes to a completely new way of thinking, and I can safely say it’s shaped the way I now look at the world of design. Because of this point I consider this project to be a success and a great way to end my university experience.